In modern industrial environments, efficiency and safety often rely on seamless user control. Control stations play a crucial role in this setup. These compact yet powerful devices enable operators to interact directly with machinery and systems, ensuring quick responses and safe operation. Whether used to initiate equipment, stop a process, or signal a fault, control stations are a key element in delivering practical control panel solutions across various industries.

From small workshops to large-scale production facilities, control stations simplify machine operation and bring consistency to industrial processes.

What Are Control Stations?

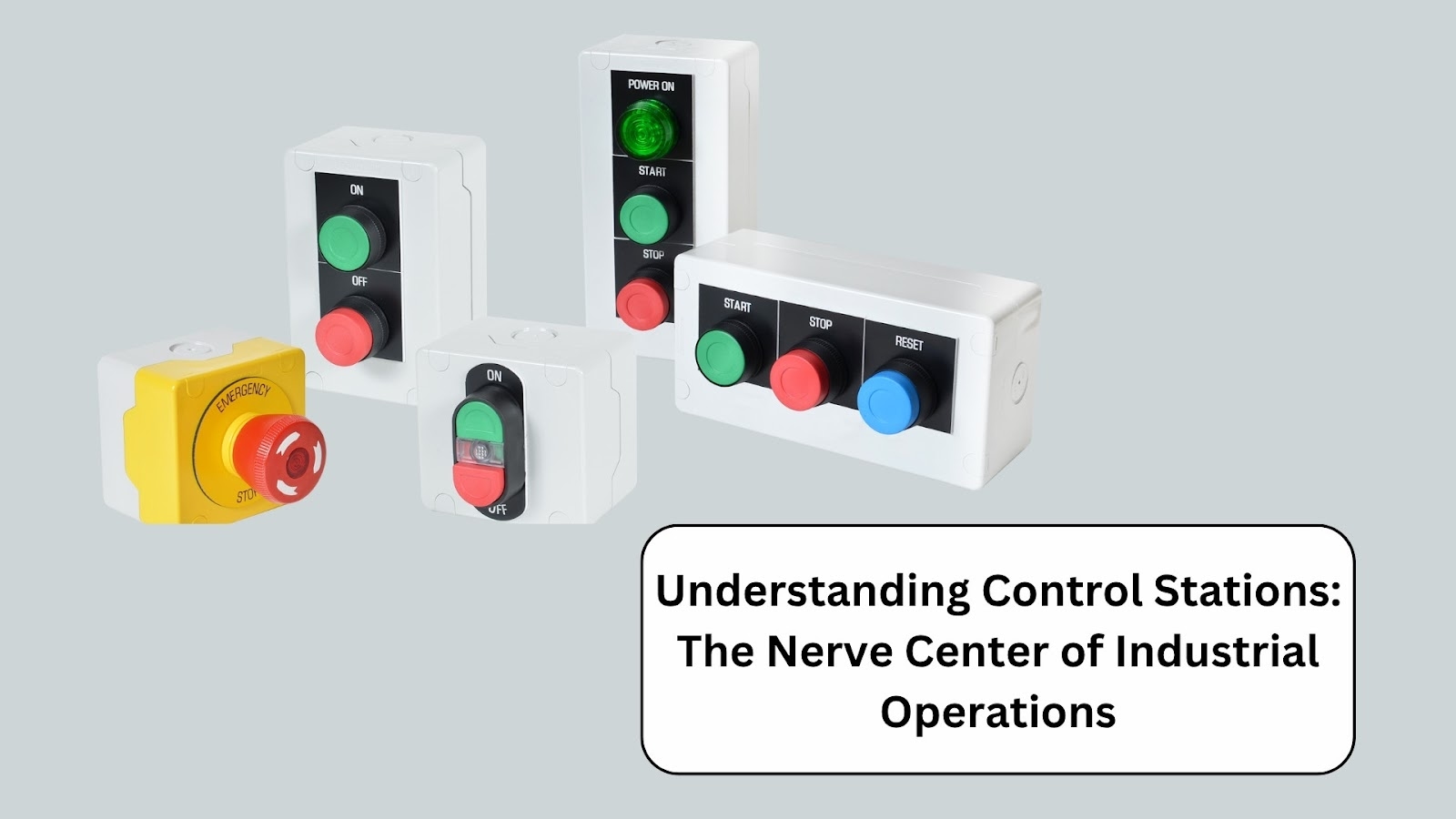

Control stations are enclosures that house essential electrical controls such as push buttons, indicator lights, and selector switches. They are typically mounted on machines or in accessible locations within a facility, allowing users to operate equipment without accessing the main control panel.

In many applications, a simple start-stop station is all that is needed. In other words, a more complex unit with multiple functions may be required. These stations offer flexibility in control while maintaining ease of use for operators on the floor.

Applications in Industrial Settings

Industrial control stations are used across a wide range of applications and industries. Common use cases include:

Starting and stopping motors and conveyors in manufacturing

Controlling HVAC systems in commercial buildings

Managing pump operations in utility and water treatment facilities

Triggering alarms or system diagnostics in industrial automation

Each use case benefits from easy access to critical controls, helping to prevent equipment damage, reduce downtime, and increase workplace safety.

Components and Configurations

While configurations vary by application, most control stations include the following components:

Start and stop push buttons

Emergency stop button (E-stop)

Selector switches for mode changes

Indicator lights for visual feedback

Protective enclosure, often rated for harsh environments

Advanced systems may also include communication capabilities or interface with programmable logic controllers (PLCs). For space-restricted installations, compact controls offer the same performance in a smaller footprint.

Importance of Control Panel Solutions

Effective control panel solutions depend heavily on how accessible and intuitive the controls are for the user. Grouping several control functions into a single station improves efficiency and reduces the risk of operator error. It also makes wiring and maintenance easier, especially when multiple machines or systems need to be controlled simultaneously.

Using modular designs, control stations can be tailored to support different types of machinery, making them a scalable solution for growing facilities.

Benefits of Control Stations

Improved safety through clearly marked, easy-to-reach controls

Increased operational efficiency by placing controls near the point of use

Durable construction for reliable operation in demanding environments

Versatile configurations that adapt to various control needs

How to Choose the Right Control Station

To select the appropriate control station for your needs, consider the following factors:

Operating environment, including exposure to dust, moisture, or chemicals

Number of control functions required

Space constraints and the need for compact designs

Certifications and compliance with industry standards

Compatibility with existing wiring and systems

Making informed choices ensures that your equipment operates efficiently and that operators can safely and effectively interact with it.

The Future of Industrial Control Is Smarter

Control stations are essential to modern industrial automation. They are not only user-friendly interfaces but also key contributors to system reliability and safety. Whether you need a simple start-stop station or a multi-function industrial control station, these devices bring together design, functionality, and protection in one accessible solution.

As businesses continue to invest in smarter operations, integrating compact controls and well-designed control panel solutions will be central to achieving safer and more efficient work environments.