AI in manufacturing is changing how factories and production lines operate. By using technologies like machine learning and smart automation, businesses can improve efficiency, reduce errors, and make faster, data-driven decisions. From quality control to predictive maintenance, AI in manufacturing helps companies stay competitive in a fast-moving industry where innovation and precision are key.

Exploring AI in Manufacturing

Artificial Intelligence is reshaping manufacturing by boosting efficiency, minimizing downtime, and improving product quality. Companies are increasingly adopting AI to stay competitive and agile in a demanding market.

Key areas where AI is transforming manufacturing:

Predictive Maintenance: AI analyzes sensor data to forecast when machines are likely to fail, reducing unplanned downtime.

Quality Control: Computer vision systems detect product defects in real time, improving consistency and reducing waste.

Demand Forecasting: AI models predict market needs more accurately, helping manufacturers plan production and inventory better.

Supply Chain Optimization: Intelligent systems streamline logistics, track materials, and respond to disruptions more effectively.

Process Automation: AI automates repetitive tasks, enhances precision, and frees up human workers for higher-value activities.

Energy Management: Smart algorithms monitor and optimize energy use across factories, leading to cost savings and sustainability gains.

Which Company Uses AI in Manufacturing?

Many leading global companies are already leveraging AI in manufacturing to gain a competitive edge. Here's how a few of them are using it:

1. General Electric (GE)

GE integrates AI across its industrial operations. It uses machine learning algorithms for predictive maintenance, allowing them to anticipate equipment failures before they happen. This minimizes downtime and extends the life of machinery.

2. Siemens

Siemens utilizes AI in its “MindSphere” platform to collect and analyze data from machines. It helps manufacturers optimize performance by detecting inefficiencies and suggesting improvements. Siemens also uses AI in robotics and automation, enabling intelligent, flexible production lines.

3. Tesla

Tesla uses AI extensively, particularly in its automated manufacturing of electric vehicles. AI helps manage robot-assisted assembly lines, quality control systems, and supply chain forecasting.

4. Bosch

Bosch combines AI with the Internet of Things (IoT) to build smart factories. Their systems track every stage of the production process and use AI to enhance product quality, monitor energy use, and improve logistics.

5. Foxconn

Foxconn, a major electronics manufacturer, uses AI in manufacturing to automate assembly, monitor worker safety, and detect defects with computer vision.

These examples show that AI is not confined to one sector—it spans automotive, electronics, energy, and beyond.

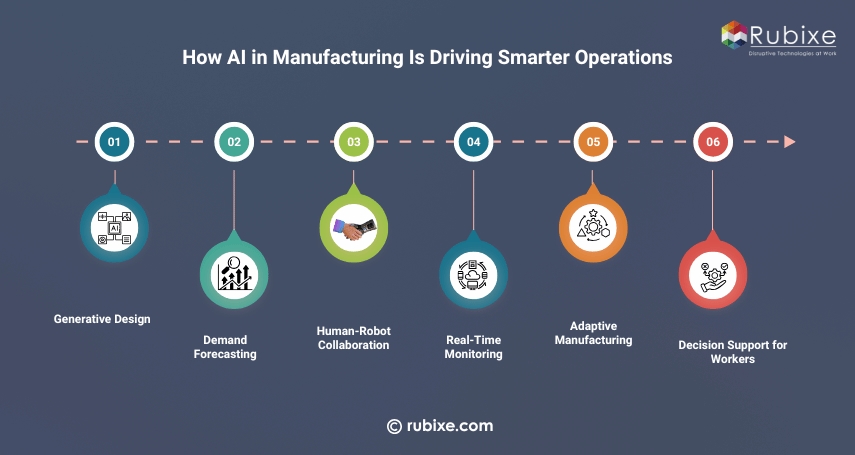

How AI in Manufacturing Is Driving Smarter Operations

AI in manufacturing is no longer limited to automation. It’s now central to transforming how factories operate—enabling systems that learn, adapt, and optimize with minimal human input.

Key applications of AI in manufacturing:

Generative Design: AI-driven tools generate design alternatives based on real-time constraints like materials, costs, and performance targets.

Demand Forecasting: Machine learning algorithms analyze historical and market data to help manufacturers plan inventory and production more accurately.

Human-Robot Collaboration: AI enables robots to work safely alongside people, adjusting actions based on human movement and intent.

Real-Time Monitoring: AI analyzes sensor data to identify production delays, quality issues, or maintenance needs before they become costly problems.

Adaptive Manufacturing: Systems using AI in manufacturing can adjust settings dynamically based on raw material conditions or external environmental changes.

Decision Support for Workers: AI tools deliver real-time alerts, recommendations, and visual dashboards to support better decisions on the factory floor.

AI and Its Impact on Manufacturing

Artificial Intelligence is driving a shift from reactive production methods to intelligent, adaptive manufacturing. Rather than automating just tasks, AI now supports higher-level decision-making and innovation across the production floor.

New areas where AI is making a distinct impact:

Intelligent Scheduling: AI dynamically reschedules production runs based on material availability, workforce shifts, and real-time order changes.

Human-Robot Collaboration: Smart AI-integrated robots work alongside humans to handle complex or ergonomically challenging tasks safely.

Real-Time Quality Feedback: AI feeds insights from sensors directly back into the design or assembly process, helping engineers adjust before issues spread.

Augmented Workforce Training: AI-powered simulations and guided instruction are used to upskill technicians and machine operators quickly.

Defect Prediction Models: Instead of catching faults after they occur, AI predicts process deviations that may lead to flaws, enabling proactive fixes.

Digital Twin Integration: AI combines with virtual replicas of production lines to test scenarios, optimize layouts, or simulate stress before making changes in the physical plant.

Driving Manufacturing Efficiency with AI Consulting

AI in manufacturing is evolving from simple automation to a strategic driver of smarter production. AI consulting helps manufacturers identify the right technologies, align them with business goals, and ensure smooth implementation across operations.

Key ways AI consulting improves manufacturing processes:

Process Optimization: Consultants review production workflows and suggest AI-driven improvements to reduce delays and waste.

Tailored AI Solutions: Manufacturers gain custom tools for tasks like predictive maintenance, quality control, and demand forecasting.

Technology Integration: AI systems are configured to work smoothly with existing ERP, MES, and IoT platforms.

Scalable Rollouts: Consultants provide clear plans to expand AI from test environments to company-wide operations.

Workforce Training: Identifying skill gaps allows teams to receive proper training and make better use of AI tools.

Effective Data Use: Guidance is given on collecting, preparing, and applying data to support informed decision-making.

Benefits of AI in Manufacturing

Implementing AI in manufacturing offers several measurable advantages:

Increased Productivity: AI enables faster production by automating repetitive tasks and optimizing workflows.

Higher Product Quality: Real-time inspection and anomaly detection reduce defects and improve final output.

Cost Reduction: Automated systems cut down labor costs, waste, and unexpected repairs.

Faster Decision-Making: AI processes data in real time, helping managers make informed decisions quickly.

Customization at Scale: AI allows for mass customization by adjusting production lines based on individual customer requirements.

The Role of AI Services and Automation

AI services encompass a wide range of tools and technologies designed to enhance industrial automation. These include cloud-based AI platforms, machine learning models, and industrial robots integrated with intelligence.

Automation backed by AI is far more flexible and adaptive than traditional automation. For example, a robotic arm equipped with computer vision and machine learning can sort products of various shapes and sizes without needing reprogramming.

Rubixe AI Company provides advanced AI services that enhance automation in manufacturing, making systems smarter, more autonomous, and capable of managing complex tasks with minimal human involvement.