Like software-as-a-service (SaaS), RaaS allows commercial or industrial operators to lease robotic systems or drones for their needs. Robots, particularly drones, have many applications that are valuable in many industries.

One of these applications is indoor inspection. In this article, we’ll try to answer what indoor inspection is and why an indoor inspection drone is important. We’ll also try to answer the advantages that inspection drones offer for different industries.

What is Indoor Inspection?

Indoor inspections can also be called internal inspections or interior inspections. They are used to determine the conditions of certain assets and identify potential defects.

Interior inspections are often conducted with the following methods:

Scaffolding

Temporary structures are typically constructed to allow inspectors to climb onto and conduct visual inspections.

Scaffolding can be the most expensive and time-consuming method for performing internal or indoor inspections. Aside from the actual construction of scaffolding, equipment or facilities also need to be powered down.

Rope Access

For at-height inspections and those in confined, inaccessible places, internal rope access is an alternative to scaffolding.

Rope access technicians often utilize a combination of safety hardware and ropes to conduct internal inspections. Rope access inspections are typically done inside industrial assets like boilers and stacks.

However, while it’s less expensive than scaffolding, rope access inspections still require certified rope access technicians.

Remote Visual Inspection

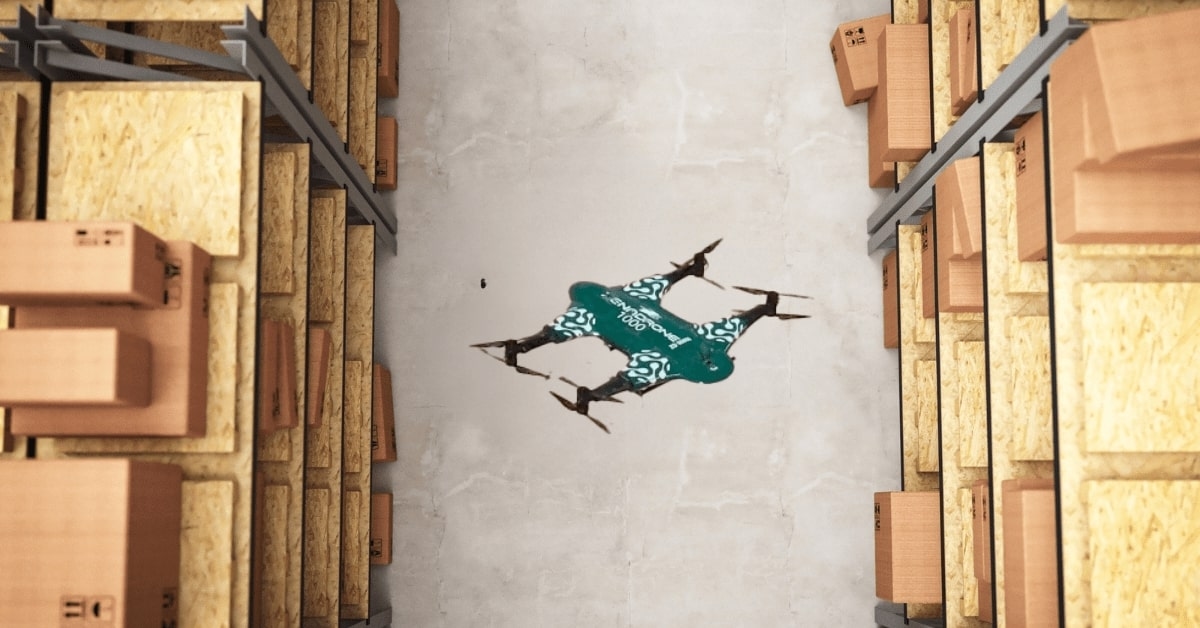

Remote visual inspection tools are cameras – typically drones – that can be sent into confined spaces. They are quickly becoming a preferred method for conducting inspections for several reasons.

Sophisticated indoor camera drones do more than ensure the safety of inspectors and other personnel. They are also cost-effective at collecting data and can even conduct minor repairs if needed.

Why is Drone Visual Inspection Important?

Regular maintenance is key for ensuring that industries adhere to safety standards. General procedures often need to be followed when maintaining assets, with inspection usually being the first.

While not all inspections are visual, drones can perform visual inspections much better alongside safety inspectors. Conducting visual inspections using an indoor drone with camera attachments is crucial for the following reasons:

Reduced Risk

Visual inspections are inherently risky because safety inspectors have to look at critical structures closely. Drones can take the place of inspection teams without risking the safety of personnel.

Speed

Drones can help entire teams perform visual inspections at a fraction of the time. They are also often easier to deploy, taking only a few minutes. Depending on their size, they can maneuver into structures like boilers and even large pipelines.

Reduced Downtime

Many structures and assets need to be shut off during inspection, such as pressure vessels and boilers. Inspections using an inside drone with camera attachments can drastically reduce the necessary downtime.

What Are the Differences Between Autonomous vs. Non-autonomous Drone Inspections?

Routine indoor inspections are critical for ensuring safety and security. Routine patrols are needed for identifying security breaches and ensuring compliance with safety standards.

To accomplish this task, companies often turn to drones to perform routine inspections. There are two types of indoor inspection using drones: autonomous and non-autonomous.

Here are the following differences between autonomous and non-autonomous indoor inspection drones:

Cost

Semi-autonomous drone inspections can cost less than human-only security checks. However, they can still cost more than fully autonomous checks. The reason for this is because of the additional cost of hiring a licensed human pilot.

Additionally, non-autonomous inspections also require the shutdown of certain facilities. The downtime can also result in increased expenses for companies.

Frequency

An autonomous indoor inspection drone can carry out automatic inspections frequently without the need for human intervention.

Safety inspections can be conducted regularly with an autonomous drone since it relies on pre-planned flight data. However, since autonomous flights rely on data, their parameters are often quite narrow.

Autonomous inspections are also less flexible as a result. When needed, they can only gather data based on their existing flight route. To change their flight route, drones need to be piloted manually.

Rapid Response

Autonomous inspections are designed with strict parameters compared to non-autonomous inspections. This is because they rely on pre-existing data from previous flights.

As a result, they may be slower compared and less flexible. Indoor inspection drones are docked at facilities and ready to go at a moment’s notice. However, for any environmental changes, pilots are required for quick maneuvering.

What Are the Advantages of an Indoor Inspection Drone?

Indoor drones open up several possibilities for companies across various industries. Aside from forgoing expensive, temporary structures like scaffolding, companies can make better and more efficient choices with the right drone.

Here are the biggest advantages that indoor drones can offer during internal inspection:

Real-time Visualization

An indoor inspection drone can provide real-time visual information to operators from a safe distance.

Using an indoor drone, operators can have access to high-quality images, video recordings, and even three-dimensional information in real-time. The data can then be processed using advanced image processing software.

Problem Location

The combination of high-quality cameras and onboard sensors allows operators to locate and identify potential issues or defects. They can do so faster than traditional inspection but also use this to make informed decisions.

Drones can also utilize 3D mapping to assess the quality of structures and assets. Onboard technologies like the following can help make accurate digital models more accessible:

RGB Cameras

Thermal Sensors

LiDAR

Precision

Nano drones are more precise not just in locating problem areas. Depending on their custom attachments, they can also be precise in making emergency repairs.

Mini drones are exceptional in navigating tight and complex spaces, making precise mapping not just possible but easier. They are essential in areas that would otherwise be difficult to access or map with human inspectors.

Documentation

Drones are great at collecting and recording data in real time. Their collected data can even be used to document the conditions of structures and assets over time throughout numerous inspections.

Using this data, inspectors can track any changes and plan their maintenance schedules accordingly. Regarding problem resolution, inspectors can use indoor camera drones to identify specific critical areas as higher priorities.

What Industries Utilize Indoor Drone Inspections?

Industrial inspections are critical for maintaining and repairing a wide array of structures and assets. Ensuring proper care and strict compliance with safety standards prevents small defects from leading to potential catastrophic failures.

Indoor drone inspections are likewise vital in many industries all over the world, such as:

Petrochemical Industry

Indoor inspection of refineries and pipelines ensures that

Here are a few of the most common assets and structures that require regular maintenance:

Boilers

Pressure vessels

Pipelines

Cokes

Fermenter tanks

Construction Industry

Drones can be used for internal structure inspection. Interiors of structures like bridges, tunnels, and buildings are often hazardous and narrow, making drones the safest option.

Indoor drone photography is great for inspecting the following in the construction industry:

Construction Sites

Safety Conditions

Onsite Stockpiles and Aggregates

Infrastructure and Utilities

During scenarios that present a potential danger to inspectors, like underground highway or railroad inspections, drones provide key visual data.

Without drones, safety inspectors would otherwise require heavy machinery to conduct visual inspections. This can take several days and be potentially dangerous for personnel.

Other structures and assets that require drone inspection include the following:

Railways

Underground highways

Tunnels

Mining Industry

Large underground holes that result from ore vein extraction can result in debris falling from the ceiling and the walls. These areas are often extremely dangerous and most countries prohibit mining personnel from entering them as a result.

Indoor camera drones are vital for ensuring safety during indoor inspections in the mining industry. The visual data they provide is essential for safety assessment, which allows unprecedented access to hazardous no-go zones.

Other mining assets that warrant inspection by drones include the following:

Drop Raises

Stockpile Feeders

Grinding Mills

Stopes

The Bottom Line

Robots-as-a-service (RaaS) allows commercial or industrial operators to lease robotic systems or drones for their needs. One of these needs is indoor inspection for various structures and assets.

Using an indoor inspection drone has many benefits that allow industries to comply with safety standards and ensure efficiency. With proper care and strict adherence to safety standards, small defects are prevented from becoming potential catastrophic failures.