The monoblock stopper rod is a critical flow-control component in the continuous casting process. Installed in the ladle or tundish slide-gate system, the stopper rod regulates molten steel flow by adjusting the opening area between the nozzle seat and its controlled orifice. Because it is directly exposed to high-temperature steel, aggressive slag chemistry, thermal shock, and mechanical load, its performance significantly influences casting stability, steel cleanliness, and product quality.

Understanding the structural characteristics, materials, degradation mechanisms, and operational best practices of the monoblock stopper rod is essential for achieving long casting sequences and minimizing risk of nozzle leakage or flow instability. This article summarizes the key technical tips every steel plant should know.

1. Understand the Structure and Working Principle of the Monoblock Stopper Rod

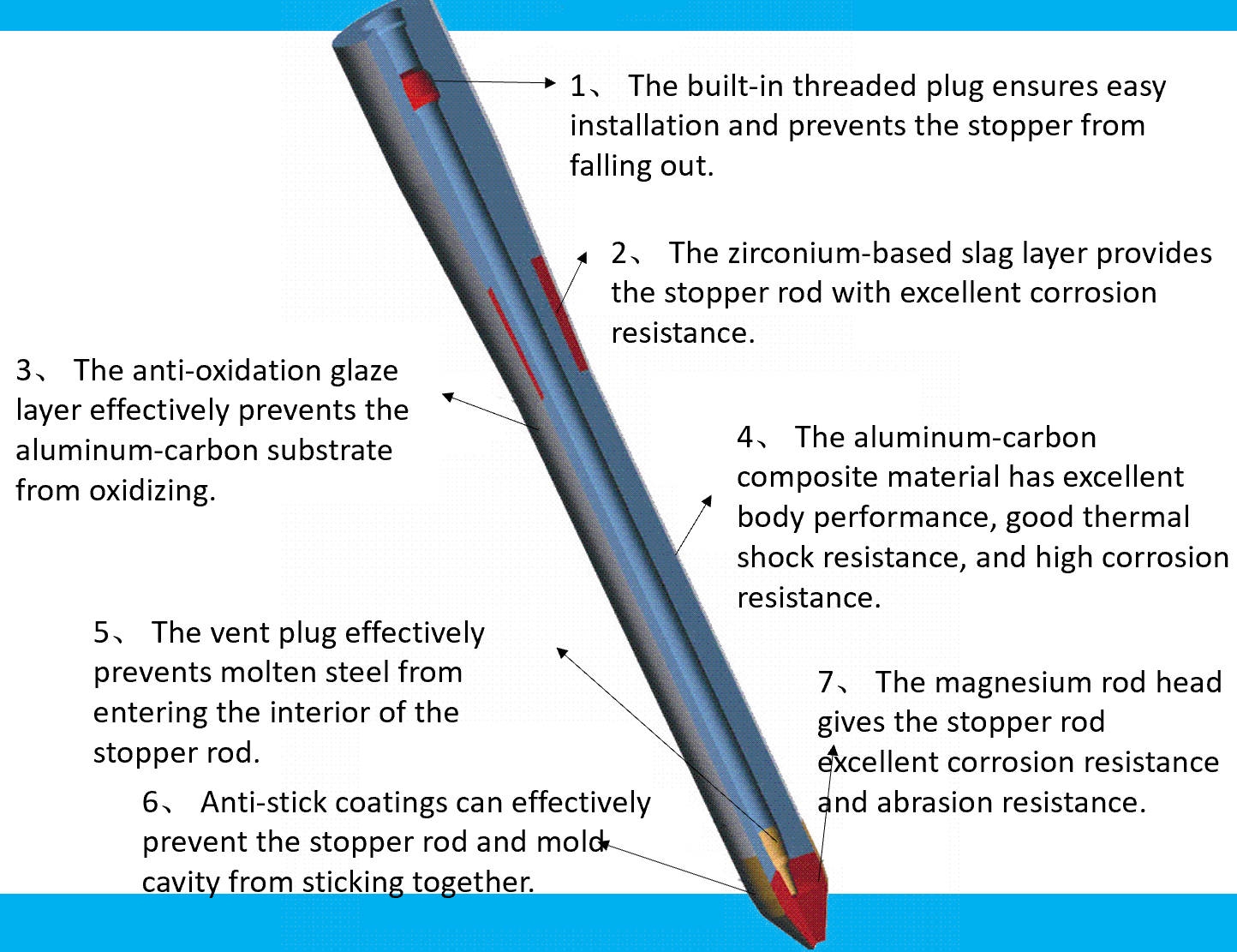

A monoblock stopper rod is a single-piece, integrated ceramic system designed to precisely control molten steel flow. It typically consists of:

Tip (Working end)

Exposed directly to molten steel

Requires high erosion resistance and thermal shock stability

Often

Body (Shaft)

Transfers mechanical force to the tip

Must be strong yet lightweight to reduce arm load

Usually alumina-graphite with high flexural strength

Up

With

Requires good dimensional tolerance and mechanical integrity

The key working principle is:

The stopper rod moves vertically to adjust the annular opening between the rod tip and nozzle seat.

This controls steel flow rate, jet length, and casting meniscus stability.

Smooth movement is essential to avoid flow surges and inclusion entrapment.

2. Choose the Proper Material System Based on Casting Requirements

Material

2.1 High-Zirconia Carbon (ZrO₂-C)

Excellent corrosion resistance against aggressive steels

Very stable against Al-killed steel environments

Preferred for long-sequence slab or bloom casting

2.2 To

Good thermal shock resistance

To

Economical and widely used

2.3 Low-Carbon or Carbon-Free Systems

Reduce carbon pick-up and CO bubble generation

Improve steel cleanliness for ultra-low-inclusion grades

Critical for interstitial-free and automotive steels

2.4 Tips for material selection

For stainless steel → use high-ZrO₂ systems

For high-aluminum steels → ensure anti-oxidation coatings

For long casting campaigns → use high-density, isopressed products

3. Pay Attention to Stopper Rod–Nozzle Seat Interaction

The interface between the stopper rod tip and nozzle seat is the most critical point in casting flow control.

Problems in this area can lead to:

Leakage

Turbulent flow

Uncontrolled casting speed

Accelerated clogging

Inclusion entrapment

Best practices:

Ensure precise geometry to achieve a uniform annular gap.

Avoid thermal mismatch between stopper rod and nozzle.

Use anti-oxidation, anti-slag-wetting coatings to reduce buildup.

Maintain alignment between stopper rod and nozzle bore.

A misalignment of even 1–2 mm can cause severe turbulence and steel quality defects.

4. Understand the Main Failure Mechanisms

A monoblock stopper rod faces multiple types of degradation. Knowing these mechanisms helps prevent premature failure.

4.1 Oxidation

Graphite in the refractory oxidizes when exposed to air or oxygen-rich slag.

→ leads to porosity growth, strength reduction, and erosion.

4.2 Slag Erosion

Basic slags (CaO-rich) or acidic slags (SiO₂-rich) dissolve refractory surfaces.

→ anti-slag coatings are essential.

4.3 Thermal Shock

The rod experiences rapid temperature change when first immersed.

→ high-modulus graphite and fine-structure alumina reduce spalling.

4.4 Mechanical Load & Wear

Vibration or actuator misalignment causes tip abrasion.

→ requires strong bonding and consistent density.

4.5 Steel–Refractory Reaction (especially in Al-killed steel)

Al₂O₃ deposition at the interface can cause:

Increased resistance to movement

Flow instability

Premature clogging

5. Control Operational Conditions to Extend Stopper Rod Life

Proper operation can increase stopper rod campaign life by 30–50%.

5.1 Preheating

Gentle, controlled preheating prevents thermal shock.

5.2 Correct Argon Injection (if applicable)

Too low → clogging increases

Too high → turbulence and re-entrainment

Optimal → improves steel cleanliness and flow stability

5.3 Smooth Actuator Motion

A jerking motion causes:

Flow surges → inclusions

Wear on the nozzle seat

Risk of breakthrough

Modern electro-servo stopper actuators provide better stability.

5.4 Accurate Stopper Position Calibration

Misalignment can:

Cause eccentric wear

Increase clogging

Lead to molten steel leakage

6. Optimize Stopper Rod Geometry for Your Casting Mode

Different casting processes require different stopper geometries.

6.1 Long strand slab casting

Use elongated tips for deeper penetration

Prefer high-ZrO₂ systems

6.2 Billet and bloom casting

Shorter tapered designs for fast response

Require high thermal shock resistance

6.3 High-speed casting lines

Aerodynamic designs to reduce flow separation

Optimized surface coatings

7. Maintenance and Inspection Tips

To ensure consistent casting performance:

Before casting:

Check for cracks, tip defects, surface spalling

Confirm actuator calibration

Verify coating uniformity

During casting:

Monitor stopper movement behavior

In

After casting:

Examine the rod and nozzle seat for:

Buy

Clogging deposits

Chemical attack zones

Documenting the damage provides guidance for future material optimization.

Conclusion

The monoblock stopper rod is a mission-critical flow-control component in continuous casting. Proper understanding of its materials, design principles, failure mechanisms, and operational considerations can significantly enhance casting stability and steel quality. By selecting high-performance materials, optimizing rod–nozzle interaction, controlling thermal and chemical environments, and maintaining precise operational control, steel plants can extend campaign life and achieve superior metallurgical results.More information,please visit HYRE