In the world of metalworking, accuracy, strength, and efficiency are critical. Whether for industrial manufacturing, custom fabrication, or artistic design, having the right sheet metal bender can define the quality and precision of your output. Selecting a dependable tool for shaping metal sheets is not just about bending—it's about control, repeatability, and craftsmanship.

Understanding the Role of a Sheet Metal Bender

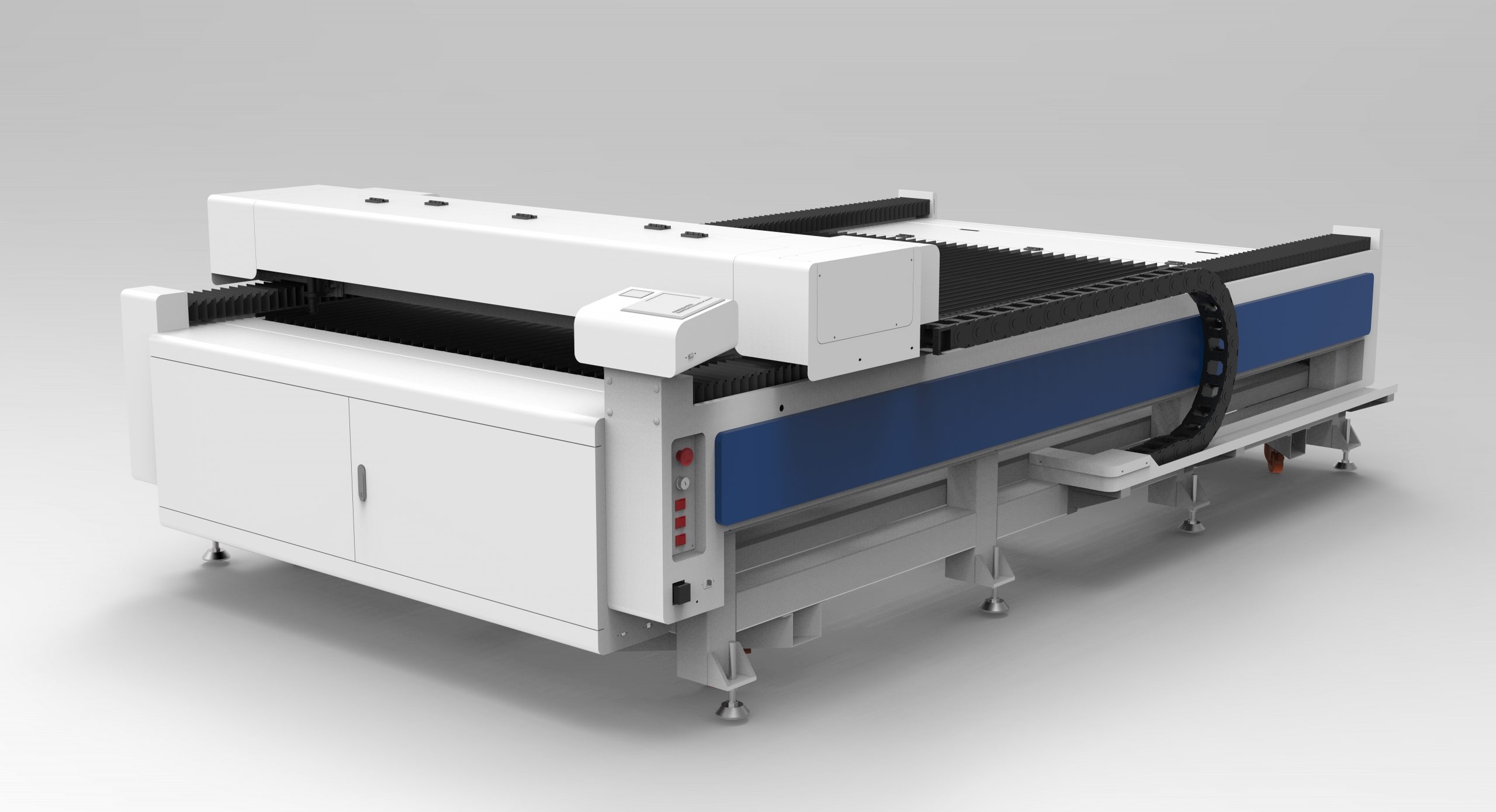

A sheet metal bender is a specialized device designed to bend and shape metal sheets to desired angles and curves. It plays a pivotal role in numerous industries including automotive, construction, HVAC, and furniture production. From forming simple flanges to complex parts, these tools are a backbone of fabrication shops.

Precision is paramount when working with metal. A high-quality sheet metal bender enables fabricators to create consistent results with minimal errors. Whether working with aluminum, stainless steel, or mild steel, the right bending tools ensure smooth operations without damaging the material.

Types of Metal Bending Tools

There are various types of metal bending tools available, each with its unique advantages. Manual brakes, hydraulic presses, and CNC-controlled benders are common options. Each type of sheet metal bender suits different project scales and complexity.

Manual Brakes: Ideal for small workshops or hobbyists. They’re cost-effective and suitable for lighter gauges.

Hydraulic Brakes: Perfect for heavy-duty tasks, these provide high force with precise control.

CNC Bending Machines: For advanced applications, these automated tools offer unmatched precision and repeatability.

Regardless of the type, a quality brake for bending metal must offer durability, ease of use, and consistent pressure across the entire bend length.

Key Features to Consider

When choosing a sheet metal bender, several features can influence performance and productivity:

Bend Radius Control: Adjustability is crucial to produce various forms without distortion.

Material Capacity: Know the thickness and types of metal your bender can handle.

Clamping System: A reliable clamping system ensures material stability during operation.

Portability vs. Stability: Some applications need mobile solutions, while others benefit from heavy-duty, stable machines.

Safety Features: Protective guards, foot pedals, and emergency stops are important in busy shop environments.

By evaluating these aspects, metalworkers can choose a bending sheet metal solution that aligns with their operational needs.

Applications in Modern Industry

From HVAC ductwork to metal enclosures and architectural elements, sheet metal benders serve a wide array of applications. Industries value them for their ability to form precise bends and folds without compromising structural integrity.

Automotive: Create custom brackets, body panels, or heat shields.

Construction: Shape flashing, roofing edges, and metal framing components.

Furniture Design: Bend tubing and metal sheets for clean, modern aesthetics.

With the right sheet metal bending brake, shops can take on both custom and volume production projects with confidence.

Why Precision Matters

Even a minor deviation in a metal bend can lead to faulty fits, compromised strength, and wasted materials. This is why professionals depend on a reliable sheet metal bender to ensure accuracy. High-tolerance production often requires tools that can replicate bends with consistent results, batch after batch.

This attention to detail makes a significant difference in end-product quality. Especially in industries with tight standards—such as aerospace or electronics—precision bending is non-negotiable.

The Evolution of Bending Equipment

The history of metal bending tools dates back centuries, evolving from basic manual techniques to today’s automated marvels. Modern sheet metal benders incorporate sophisticated technology like digital readouts, angle indicators, and programmable settings. These innovations improve both speed and accuracy.

What once took hours of manual effort can now be done in minutes—with less strain and greater reliability. As digital integration grows, bending tools are also becoming smarter, allowing operators to monitor and adjust operations with greater control.

Training and Skill: Still Essential

While machines play a significant role, operator skill remains vital. A quality sheet metal bender in the hands of a knowledgeable technician yields superior results. Understanding metal properties, bend allowances, and spring-back behavior is essential for effective use.

Training in proper techniques not only ensures product quality but also extends the life of the equipment. Whether using a basic brake for bending metal or an advanced CNC model, skill development pays long-term dividends.

Investing in the Right Tools

For small businesses and large-scale operations alike, investing in dependable metal bending tools is a strategic move. Equipment that delivers clean, accurate bends reduces rework, increases throughput, and enhances customer satisfaction.

The key is to find a balance between budget, performance, and future growth. Modular systems or expandable machines can grow with your business needs.

Brands like Zintilon, though mentioned subtly here, are known for producing robust tools that support professionals in their craft—tools that perform reliably over time without compromise.

Maintenance and Longevity

To keep your sheet metal bender in optimal condition, regular maintenance is essential. This includes:

Cleaning and lubricating moving parts

Inspecting dies and clamps for wear

Calibrating angles and controls

Ensuring alignment and flatness of beds

Preventive maintenance not only prevents breakdowns but also maintains bending accuracy, keeping your shop running efficiently.

Conclusion: Power and Precision at Your Fingertips

In any fabrication environment, the sheet metal bender is more than a machine—it’s a precision partner. It empowers craftsmen, engineers, and manufacturers to bring designs to life with confidence. Whether shaping a single custom piece or producing thousands, the right tool makes all the difference.

Choosing a high-quality sheet metal bending brake isn’t just an equipment decision—it’s a business strategy. It ensures quality, speed, and consistency while building trust with clients who depend on flawless execution.

For professionals looking to elevate their craft, a dependable sheet metal bender is a foundational investment. With the right knowledge, proper care, and a commitment to quality, it's possible to transform plain sheets into functional, beautiful, and precise metalwork—again and again.